As an indispensable means of transportation in modern society, the quality and safety performance of buses are directly related to the safety and comfort of passengers. As an advanced surface treatment technology, electrophoresis plays a vital role in the manufacturing process of buses.

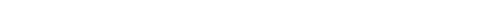

Electrophoresis, in short, is the directional movement of charged particles in the electrolyte through the action of electric field, thus realizing the coating of the surface of the object. In the field of bus manufacturing, electrophoresis technology is mainly used for body painting, the principle of which is to immerse the bus body into the electrophoresis liquid with pigment, and then make the pigment particles adhere to the surface of the bus body through electrification to form a layer of homogeneous and dense paint film.

The application of electrophoresis technology in bus manufacturing not only improves the uniformity and adhesion of the coating, but also greatly enhances the corrosion and abrasion resistance of the coating. Compared with the traditional paint spraying process, electrophoresis technology is more environmentally friendly, which can reduce the waste of paint and the emission of waste gas, and is in line with the modern manufacturing industry’s pursuit of green and environmental protection.

In addition, the application of electrophoresis technology also significantly improves the appearance quality of buses. After electrophoresis treatment of the bus surface, the paint film is flat and smooth, and the color is bright and long-lasting, which not only improves the overall aesthetics of the bus, but also increases the pleasure of passengers.

With the continuous progress of science and technology, electrophoresis technology is also being updated and its application fields are also expanding. In the future, electrophoresis technology will play a more important role in the manufacture of buses and contribute more to the technical innovation and quality improvement of the bus industry.

Post time: Apr-11-2024